The LAMBDA MINIFOR Bioreactor-Fermenter used in the fusion of biocarrier matrix and microbes

LAMBDA MINIFOR Fermenter-Bioreactor used in establishing Microbial Ecosystem within the Bio-Carrier.

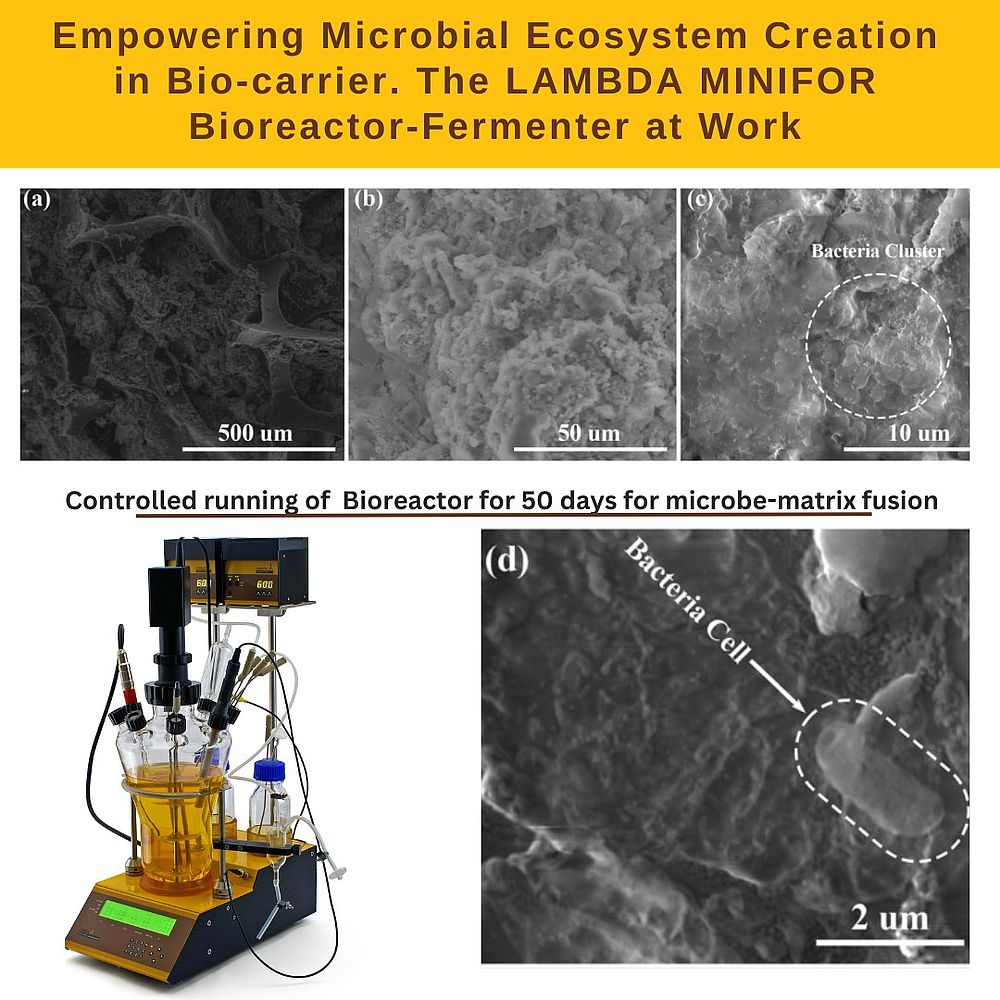

Fig 1: Empowering microbial ecosystem creation in Biocarrier. The LAMBDA MINIFOR Fermentor-Bioreactor at work.

The increasing demand for coal by industries has resulted in a significant amount of coking wastewater containing highly toxic, carcinogenic, mutagenic, and challenging pollutants. Effectively removing these organic pollutants from complex industrial wastewater remains a major concern. Although biological treatments are commonly used, they only partially degrade the contaminants, leading to the emergence of toxic nitrogenous compounds, such as nitrate (NO3) and nitrite (NO2), which are harmful to the existing microbes in the wastewater.

To tackle this challenge, a group of teams from China developed an efficient biocatalytic microbial ecosystem using a porous bio-carrier made of a functional polyurethane sponge. This ecosystem comprised a unique group of organisms that they called as RODMs, which were obtained from hazardous sites and possessed novel metabolic capabilities for effectively degrading highly-concentrated aromatics in the wastewater. To sustain and enhance the RODMs' performance, strategic enzyme immobilization was employed. This involved introducing oxidation and reduction enzymes directly onto the functional polyurethane sponge bio-carrier, facilitating efficient enzymatic catalysis of stubborn organics and effective degradation of organic compounds.

Reference: Ahmad, M., Yousaf, M., Han, J.-C., Huang, Y., Zhou, Y. & Tang, Z. (2023). Development of Biocatalytic Microbial Ecosystem (FPUS@RODMs@In-PAOREs) for Rapid and Sustainable Degradation of Various Refractory Organics. Journal of Hazardous Materials, 2023, 131514, ISSN 0304-3894, https://doi.org/10.1016/j.jhazmat.2023.131514

In the development of the microbial ecosystem, a LAMBDA MINIFOR bioreactor was used to create a densely populated community of RODMs. Half of the LAMBDA MINIFOR 7L bioreactor was filled with the functional polyurethane sponge, and the required nutrient media for microbial growth was supplied with a hydraulic retention time of 12 hours.

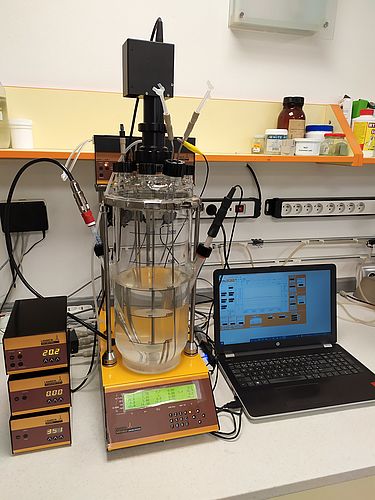

Fig 2: The LAMBDA MINIFOR 7L Bioreactor with SIAM fermentation software for remote control and data acquisition.

The isolated RODMs seed sludge was added to the LAMBDA MINIFOR bioreactor, and the polyurethane membrane and RODMs were thoroughly mixed. Conditions and parameters were continuously monitored for 50 days until the successful fusion of the microbial community with the functional polyurethane bio-carrier.

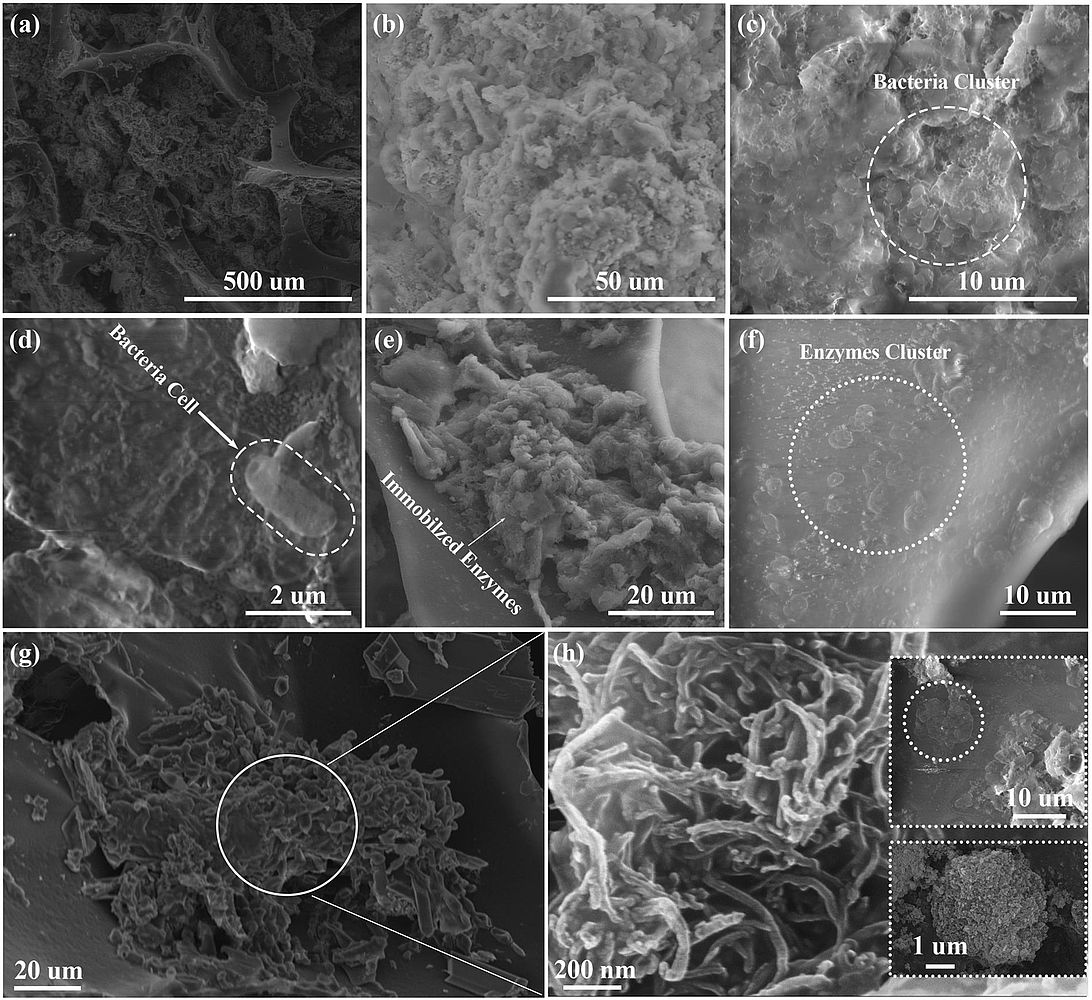

Figure 3: FESEM picture illustrates the characterization of microbes, the biofilm matrix, enzyme immobilization, and their consistent growth on the Functional Polyurethane Sponge (FPUS) bio-carrier. (Credit and Source: Ahmad, M., Yousaf, M., Han, J.-C., Huang, Y., Zhou, Y. & Tang, Z. (2023). Development of Biocatalytic Microbial Ecosystem (FPUS@RODMs@In-PAOREs) for Rapid and Sustainable Degradation of Various Refractory Organics. Journal of Hazardous Materials, 2023, 131514, ISSN 0304-3894, doi.org/10.1016/j.jhazmat.2023.131514)

a) Formation of a compact and porous microbial ecosystem over the FPUS, with microbial biomass thriving within FPUS pores. This location fosters the creation of networks along FPUS walls.

b) Visual representation of the biofilm matrix, consisting of a variety of enzymes and microbial groups interconnected by components of Extra Polymeric Substances.

c) Microbial clusters within the intricate biofilm matrix.

d) Depiction of a single bacterial cell with an approximate size of 2 μm.

e) Enzyme aggregation on the porous surfaces of the FPUS.

f) Functional enzymes forming small 3D aggregates.

g) Aggregation of enzymes on the bio-carrier walls.

h) Enzymes adopting diverse structures to efficiently carry out bioactivities within a shared space.

Result:

The developed system (Functional Polyurethane Matrix + RODMs + Enzyme immobilization) demonstrated an improvement in the removal rate of refractory organics to 4 kg/m3/day. This enhancement can be attributed to the enzymatic catalysis of refractory organics (at a concentration of 2000 mg/L) along with the concurrent reduction of COD (1200 mg/L).

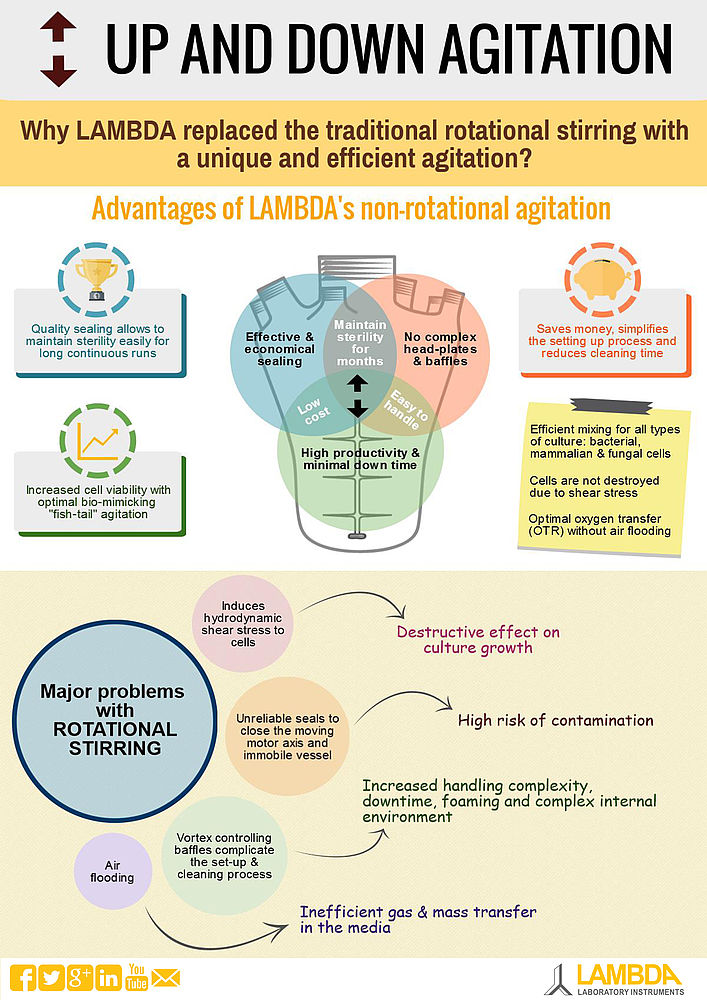

Why LAMBDA MINIFOR is Ideal for Shear-Sensitive Cells and Materials?

Introducing the Ultra-Gentle "Fish-Tail" Agitation in the LAMBDA MINIFOR Fermentor: The LAMBDA proudly present the revolutionary "Fish-Tail" stirring disc, a product born from the ingenious design of a fish's tail in the Bioreactor from working volume 35ml - 6L . This unique innovation offers a soft and nurturing agitation solution, emulating the graceful motion of a fish's tail fins in the water. Through the rhythmic up-and-down motion of one or multiple "Fish-Tail" stirring discs, a delicate mixing action is achieved, encompassing both horizontal and vertical orientations. Remarkably, this method enhances efficiency while obviating the need for cutting edges and micro-eddies—common features of traditional impellers found in bioreactors. The direct result is an augmentation in cell viability.

Ordinary stirrers, with their potentially damaging cutting edges, can compromise the integrity of delicate cells and shear sensitive materials like sponge biocarrier. Even rounded stirrers can lead to undesirable eddies. The dilemma emerges: prioritizing gas exchange and oxygenation while risking cell damage, or protecting cells and sacrificing gas exchange efficiency?

Nature provides a solution that predates human existence: the fish tail agitator. Its streamlined shape propels fish through water without creating disruptive eddies. Inspired by this design, we have crafted a agitator for the LAMBDA MINIFOR Bioreactor-Fermentor that mimics the fish tail's efficiency while eliminating the risk of cell damage. The 'Fish-Tail' stirring disc boasts a thin and gentle rim that ensures cells remain intact, even during high-efficiency mixing. This means that with our 'Fish-Tail' technology, you can achieve optimal aeration in cell cultures without compromising their well-being.

Say goodbye to the trade-off between gas exchange and cell protection. Embrace the future of gentle yet efficient mixing with our groundbreaking 'Fish-Tail' agitation technology. Discover a new realm of possibilities where your cell cultures and sensitive materials thrive.

For more details regarding the LAMBDA MINIFOR fermenter-bioreactor, please visit www.fermentador-bioreactor.com/features/ and explore the innovations of the MINIFOR fermentor-bioreactor at www.lambda-instruments.com/fermenter-bioreactor/innovations-of-minifor-fermentor-bioreactor/ .

If you have any inquiries, require a quotation, or need pricing information for our fermentor-bioreactor system, feel free to reach out to us at sales@lambda-instruments.com.